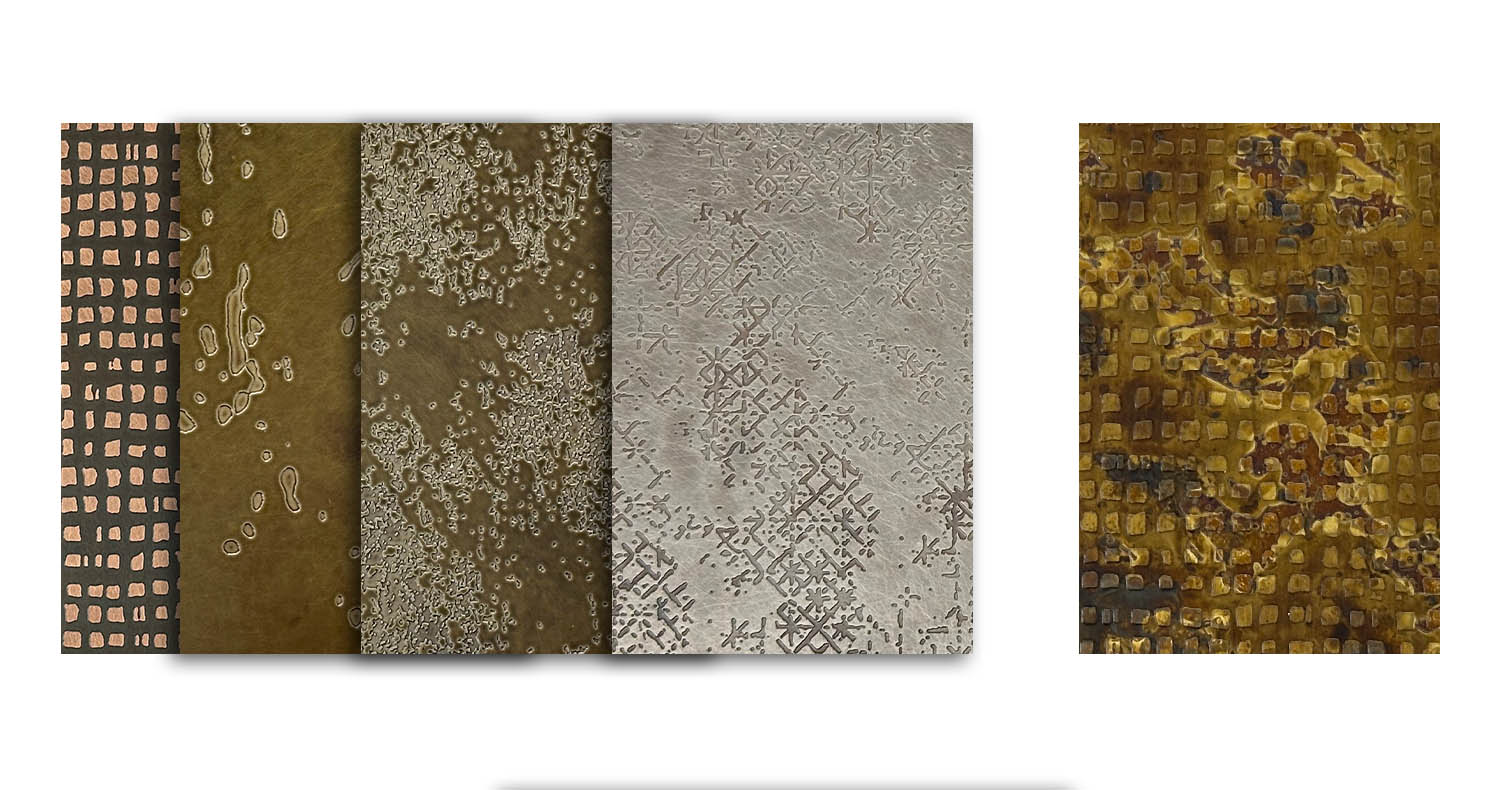

في عالم التشطيبات السطحية المتميزة، لمسة نهائية من خط الشعر البرونزي برز هذا الطلاء كخيارٍ مُفضّل للمصممين الذين يسعون إلى مزج الرقي الصناعي مع الدفء العضوي. هذا الملمس المُصمّم بعناية فائقة - والذي يتميز بأخاديده الدقيقة المتوازية ولمساته البرونزية الباهتة - يُعيد تعريف الفخامة في العمارة والديكورات الداخلية وتصميم المنتجات. دعونا نستكشف لماذا أصبح هذا الطلاء النجم الصامت في المشاريع الراقية، وكيف تُعيد تطبيقاته طويلة المدى تشكيل مواصفات المواد.

على عكس المعادن المصقولة القياسية، يجمع خط الشعر البرونزي بين ثلاث طبقات من الحرفية:

الطبقة الأساسية:ركيزة من الفولاذ المقاوم للصدأ 316L (سمك 0.5-3 مم)

دمج الألوان: طلاء برونزي PVD (سمك 2-5 ميكرومتر)

هندسة الملمس:فرشاة كاشطة اتجاهية (دقة حبيبات 150-220)

هذا الثلاثي يخلق:

عمق: أخاديد خطية 0.02-0.1 مم تلتقط الضوء بزوايا تتراوح بين 15 درجة و75 درجة

متانة:تصنيف صلابة قلم الرصاص 3H لمقاومة الخدش

استقرار اللون:يحافظ الطلاء المقاوم للأشعة فوق البنفسجية على اللون لمدة تزيد عن 15 عامًا

تكمن القوة الحقيقية لتشطيب خط الشعر البرونزي في متغيراته المتخصصة:

"كسوة برونزية مضادة للميكروبات بلمسة نهائية شعرية"

وتقوم المستشفيات في سيول الآن بتحديد هذا النوع من الطلاء لألواح المصاعد، وذلك من خلال الاستفادة من أيونات النحاس في الطبقة البرونزية لتقليل انتقال مسببات الأمراض بنسبة 68%.

"أنظمة واجهات برونزية عاكسة لأشعة الشمس"

تستخدم أبراج دبي التي تستجيب للمناخ خصائصها في تشتيت الضوء بنسبة 85% لخفض أحمال التبريد بنسبة 22%.

"بلاطات مطبخ برونزية مقاومة للتشوه بتصميم خطوط رفيعة"

تقوم العلامات التجارية السويسرية للأجهزة بربطها بمواقد الحث، مستغلة استقرارها الحراري في نطاق يتراوح بين -50 درجة مئوية إلى 300 درجة مئوية.

"ألواح صوتية برونزية خفيفة الوزن بلمسة نهائية دقيقة"

تجمع مراكز المؤتمرات في مدينة نيويورك بين القوام الدقيق والثقوب الدقيقة لامتصاص الصوت بنسبة 0.85 NRC.

"أجهزة ذكية مقاومة لبصمات الأصابع بلمسة نهائية برونزية لامعة"

تعتمد شركات التكنولوجيا العملاقة على سطحها المقوى بـ HV380 في الأجهزة القابلة للارتداء المتميزة.

"تصميمات داخلية لليخوت مصنوعة من البرونز البحري"

مع مقاومة رذاذ الملح لمدة 10000 ساعة، فإنه يحل محل خشب الساج على اليخوت الفاخرة.

تهيمن اللمسة البرونزية على مشاريع البناء الخضراء من خلال:

ألواح مركبة برونزية قابلة لإعادة التدوير (معدل استرداد الحلقة المغلقة 92٪)

طلاءات برونزية دقيقة ذات تشطيب شعري منخفض المركبات العضوية المتطايرة (تتوافق مع معايير LEED v4.1 EQc2)

إنتاج خط الشعر البرونزي السلبي للكربون (باستخدام سلائف PVD ذات الأساس البيولوجي)

حقق مجمع مكاتب في ميونيخ شهادة الصفر الصافي من خلال استخدام 15000 متر مربع من هذا الطلاء كعاكسات للحرارة المشعة، مما أدى إلى خفض استخدام الطاقة بنسبة 31%.

المشتقات المبتكرة تخلق فرصًا جديدة للكلمات الرئيسية:

| تشطيب متخصص | المواصفات الفنية | التطبيقات الرئيسية |

|---|---|---|

| خط الشعر البرونزي الدائري | أخاديد متحدة المركز 0.05 مم | أقراص الساعات الفاخرة، أبواب المصاعد |

| خط شعر برونزي متقاطع | خطوط متقاطعة بزاوية 30°-45° | لفات الأعمدة المعمارية |

| خط الشعر البرونزي المتدرج | اختلاف سمك الطلاء من 5 إلى 15 ميكرومتر | أسطح التركيبات الفنية |

| خط الشعر البرونزي الهولوغرافي | أنماط حيود النانو المنقوشة | وحدات عرض البيع بالتجزئة |

عرض متحف تيت مودرن في لندن مؤخرًا منحوتة حركية باستخدام ألواح ذات خطوط شعرية برونزية حرارية التي تكشف الأنماط المخفية عند لمسها.

تحليل جاذبيتها الاقتصادية:

كفاءة المواد:تحل صفائح الشعر البرونزية مقاس 1.2 مم محل البرونز الصلب مقاس 3 مم عند 1/4 الوزن

توفير التثبيت:تعمل الألواح الجاهزة على تقليل العمالة في الموقع بنسبة 40%

القيمة مدى الحياة: ضمان لمدة 25 عامًا مقابل 8-10 سنوات للمعادن المطلية

أفاد أحد مطوري أبراج طوكيو الشاهقة بتسريع عمليات الإيجار للمكاتب بنسبة 19% أنظمة تقسيم صوتية برونزية بلمسة نهائية دقيقة، مما يثبت أهميته في السوق.

يتضمن الجيل القادم من تقنية خط الشعر البرونزي ما يلي:

"طلاءات برونزية ذاتية الشفاء": تعمل الكبسولات الدقيقة على إصلاح الخدوش البسيطة (<0.3 مم) في 72 ساعة

"أسطح شعرية برونزية موصلة":الدوائر المضمنة للبيئات التي يتم التحكم فيها باللمس

"واجهات برونزية شعرية محفزة ضوئيًا":الطلاءات الغنية بثاني أكسيد التيتانيوم التي تعمل على تحييد الملوثات الجوية

معرض المواد الذكية 2024 في سيول يسلط الضوء جدران برونزية بتشطيبات شعرية مدمجة مع إنترنت الأشياء التي تراقب الضغوط الهيكلية مع الحفاظ على النقاء الجمالي.

خاتمة

من أثاث خارجي بلمسة نهائية برونزية التي تتحمل الطقس بشكل أنيق شاشات لمس برونزية طبية عالية الجودة يُحدث هذا الطلاء ثورةً في الواجهات الصحية، ويُثبت تنوعه في مختلف الصناعات. قدرته على تلبية المواصفات الفنية (مثل "أقسام برونزية مقاومة للحريق بتشطيبات شعرية") واحتياجات التصميم العاطفية (فكر "إضاءة صناعية دافئة بلمسة نهائية برونزية") يجعلها المادة المثالية للتغيرات المستمرة. مع استمرار المصنعين في تجاوز الحدود بمنتجات متنوعة مثل "لوحات بيضاء مغناطيسية برونزية بلمسة نهائية شعرية" و مقابض أبواب برونزية مقاومة للميكروباتهناك أمر واحد واضح: انتهى عصر الأسطح السلبية. أهلاً بكم في عصرٍ يروي فيه كل خدش قصة، ولكل بريق غرض.

Office address: 26 Floor, Shibo Financial Center, Fenjiang South Road No.38, Chancheng, Foshan, GuangDong, China

Office address: 26 Floor, Shibo Financial Center, Fenjiang South Road No.38, Chancheng, Foshan, GuangDong, China  Phone

: +86 -18024913898

Phone

: +86 -18024913898 البريد الإلكتروني

: [email protected]

البريد الإلكتروني

: [email protected] IPv6 دعم الشبكة

IPv6 دعم الشبكة

اترك رسالة

اترك رسالة