في صناعة البناء الحديثة، لوحات زخرفية من الفولاذ المقاوم للصدأ أصبحت الخيار المفضل للعديد من المشاريع الهندسية والمصممين بسبب خصائصها الفريدة الجماليات والمتانة والتنوعبالمقارنة مع مواد البناء التقليدية، فهي لا توفر جاذبية تصميمية فائقة فحسب، بل تلبي أيضًا المعايير العالية لـ الجماليات البنيوية وعمر الخدمة.

يقوم هذا المقال بتحليل شامل للقيمة المتعددة الأبعاد للألواح الزخرفية المصنوعة من الفولاذ المقاوم للصدأ في الهندسة المعمارية - بما في ذلك إرشادات اختيار المواد ومجالات التطبيق ودراسات الحالة الواقعية ونصائح الصيانة - لتوفير رؤى عملية ومهنية لأصحاب المشاريع والمشترين والمصممين.

مقاومة استثنائية للتآكل:مقاومة طويلة الأمد للرطوبة والأحماض والقلويات ورذاذ الملح وغيرها من البيئات القاسية.

قوة عالية ومرونة:مناسب للتطبيقات الهيكلية مثل كسوة الأعمدة والجدران الستارية والدرابزين.

عمر خدمة ممتد:تستمر عادةً لأكثر من 30 عامًا مع الحد الأدنى من احتياجات الاستبدال.

صديق للبيئة:قابلة لإعادة التدوير بالكامل، وغير سامة، ومتوافقة مع شهادات البناء الأخضر.

ملمس معدني مميز يكمل الأنماط المعمارية الحديثة، والصناعية، والبسيطة، أو الفاخرة.

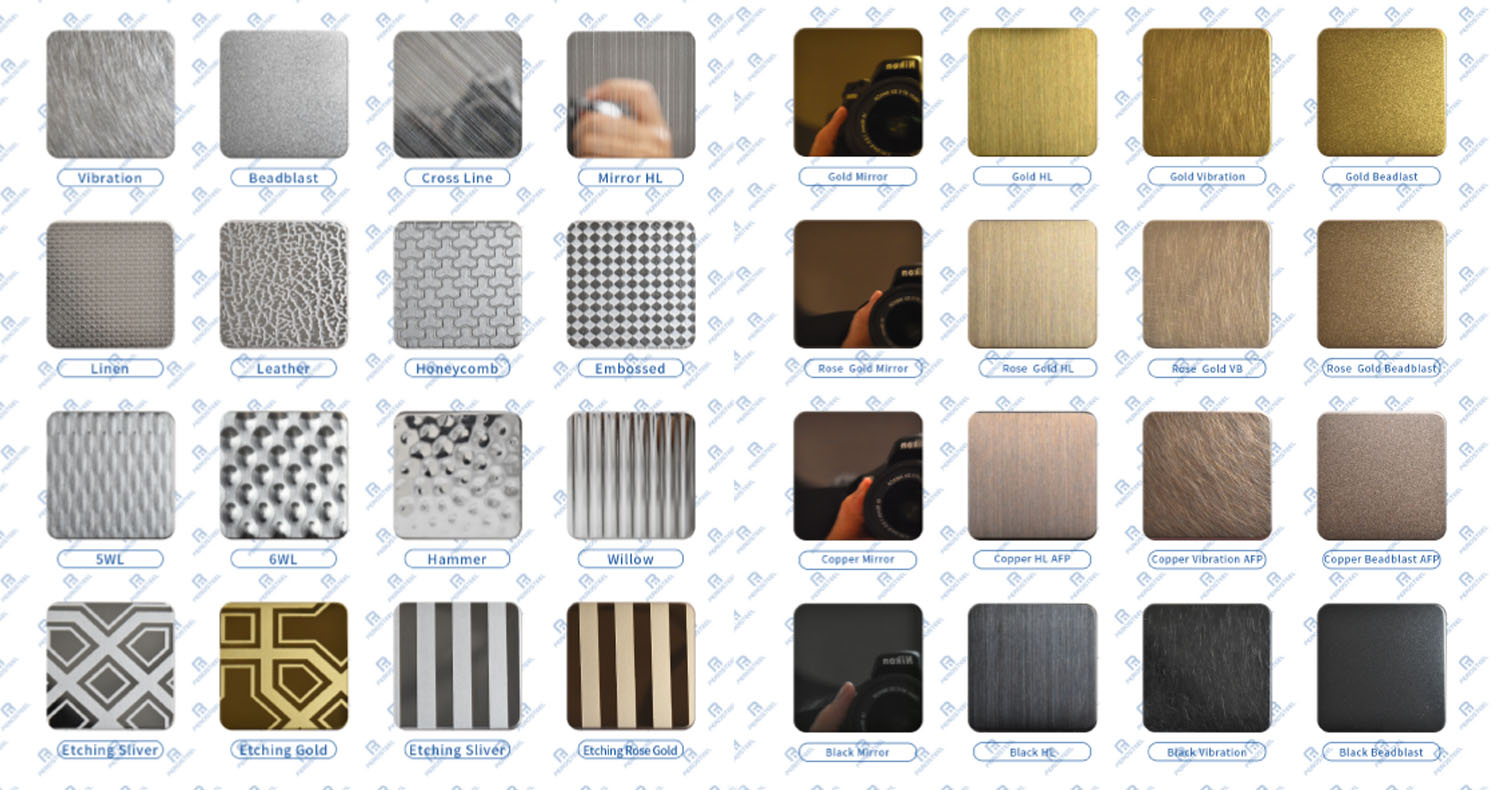

تشطيبات قابلة للتخصيص مثل مرآة، مصقولة، محفورة، مصقولة بالرمل، بارزة، متموجة (موجة مائية)، وطلاء PVD تمكين إمكانيات التصميم غير المحدودة.

يعزز انعكاس الضوء الممتاز الإدراك المكاني والتأثير البصري.

| مجال التطبيق | نوع اللوحة الموصى به | الميزات الرئيسية |

|---|---|---|

| الجدران الستارية الخارجية | تيتانيوم ذهبي مطلي بطبقة PVD، محفور بالرمل | مظهر ممتاز، مقاومة للعوامل الجوية |

| التصميمات الداخلية لسيارات المصعد | مرآة، مصقولة مضادة لبصمات الأصابع | لمعان عالي، سهل التنظيف |

| أسقف بهو المركز التجاري/الفندق | مرآة، تموج، منقوش | انعكاس مكاني معزز |

| جدران مميزة/شعارات | محفور، محفور بالليزر، مصقول بالفرشاة | عرض العلامة التجارية المخصصة |

| درابزين السلالم/السلالم المتحركة | مصقول، مضاد لبصمات الأصابع | مقاوم للانزلاق، متين |

| الجدران/الأقسام الداخلية | منقوش، محفور، متموج | أنماط زخرفية قابلة للتخصيص |

| أسطح المطبخ/الخزانة | مضاد لبصمات الأصابع، مصقول بالرمل | مقاوم للبقع وسهل الصيانة |

💡 دراسة الحالة:في مشروع فندقي سعودي من فئة 5 نجوم، ألواح محفورة بتقنية PVD باللون الذهبي الوردي تم استخدامها في جدار مميز في الردهة، مما أدى إلى رفع المستوى الجمالي مع تعزيز هوية العلامة التجارية من خلال الأنماط المخصصة.

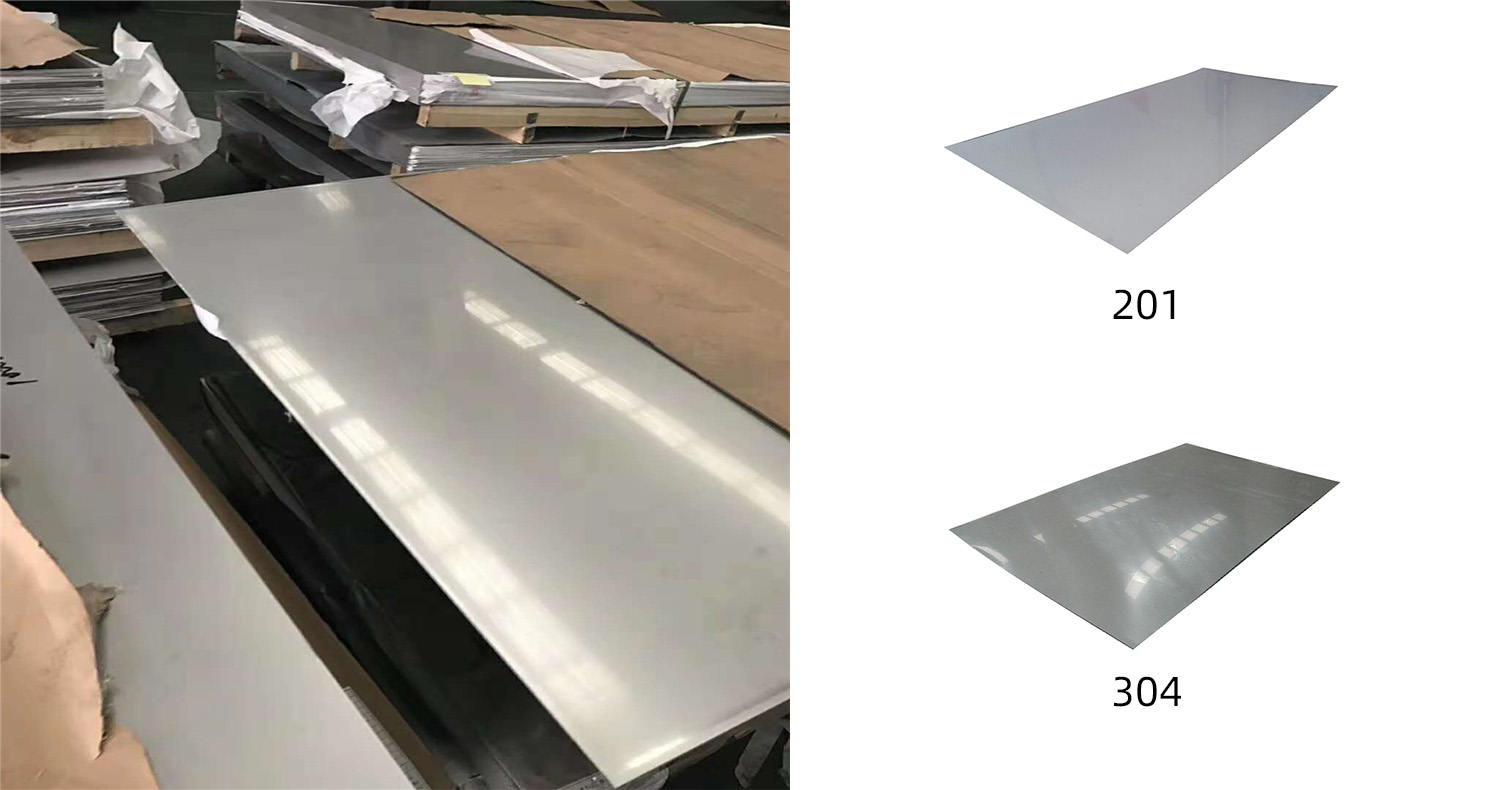

الفولاذ المقاوم للصدأ 304:درجة عالمية لمعظم المشاريع الداخلية / الخارجية.

الفولاذ المقاوم للصدأ 316:معزز بالموليبدينوم لمقاومة الكلوريد (مثالي للمناطق الساحلية/عالية الرطوبة).

201 الفولاذ المقاوم للصدأ:فعالة من حيث التكلفة للبيئات الداخلية ذات التآكل المنخفض.

| الحاجة الوظيفية | النهاية الموصى بها | الميزة الرئيسية |

|---|---|---|

| انعكاسية عالية | تلميع المرآة | يزيد من الإدراك المكاني |

| مقاومة للخدش/بصمات الأصابع | مصقول مضاد لبصمات الأصابع | مثالي للمناطق التي يتم لمسها كثيرًا |

| ديكور مخصص | محفور | يدعم الشعارات/الأنماط |

| تأثيرات الإضاءة الديناميكية | تموج (موجة مائية) | إنشاء انعكاسات متعددة الطبقات |

| طلب | نطاق السُمك |

|---|---|

| الأسقف/الجدران المميزة | 0.5 – 0.8 ملم |

| الجدران الستارية الخارجية | 1.0 – 2.0 مم |

| ألواح أبواب المصاعد | 1.0 – 1.5 ملم |

| كسوة الأعمدة/الدرابزين | 1.0 – 2.0 مم |

الأسطورة 1:"الفولاذ المقاوم للصدأ 201 مناسب للاستخدام في الهواء الطلق" → عرضة للصدأ؛ استخدم 304/316 بدلاً من ذلك.

الأسطورة 2:"يمكن قطع جميع الألواح بحرية" → تتطلب الألواح المطلية بتقنية PVD القطع بالليزر لمنع انفصال الحواف.

الأسطورة 3:"الفيلم الواقي اختياري" → احتفظ بالفيلم حتى التثبيت لمنع الخدوش/الأكسدة.

استخدم مواد لاصقة مخصصة للفولاذ المقاوم للصدأ ومثبتات غير ملوثة.

قم بفحص الألواح بحثًا عن الخدوش/اختلافات اللون قبل التثبيت.

قم بالتنظيف باستخدام منظف محايد وقطعة قماش ناعمة؛ وتجنب المنظفات الحمضية/القلوية.

تعمل التشطيبات المضادة لبصمات الأصابع على تقليل تكرار التنظيف في المناطق ذات الحركة المرورية الكثيفة.

| معيار | الاعتبارات الرئيسية |

|---|---|

| مجموعة المنتجات | توفر الألوان والتشطيبات والسمك والسبائك |

| إمكانيات التخصيص | دعم الحفر والقطع والانحناء والتلوين بتقنية PVD |

| تجربة المشروع | محفظة في المجمعات التجارية والمطارات والفنادق |

| التعبئة والتغليف والخدمات اللوجستية | التعبئة والتغليف المقاوم للخدش والخبرة في التصدير |

| الدعم الفني | فريق خدمة ما بعد البيع والهندسة سريع الاستجابة |

✅ الشريك الموصى به: فيروستيل شركة متخصصة في تصنيع الفولاذ المقاوم للصدأ المعماري بخبرة تزيد عن عشر سنوات. تقدم مجموعة واسعة من المنتجات (المرآة، المصقولة، المحفورة، البارزة، المتموجة، المطلية بتقنية الترسيب الفيزيائي للبخار)، وتدعم التصاميم المخصصة والشحن العالمي.

س١: هل يُمكن استخدام الفولاذ المقاوم للصدأ الملون في جدران الستائر؟ هل سيتلاشى لونه؟

ج: نعم. تتميز الألواح المطلية بتقنية PVD بألوان مقاومة للأشعة فوق البنفسجية، ومقاومة استثنائية للبهتان، ومتانة عالية في مواجهة العوامل الجوية، مما يجعلها مثالية للاستخدام الخارجي.

س2: هل يمكن تخصيص الألواح بالشعارات أو الأنماط؟

ج: نعم. يتيح الحفر أو النقش بالليزر تخصيصًا عالي الدقة للجدران المميزة/المميزة.

س3: ما هو أفضل سمك للسقف المرآة؟

ج: يضمن طلاء المرآة 8K مقاس 0.6 مم أو 0.8 مم انعكاسية مثالية وتركيبًا آمنًا.

س4: هل يمكنكم تسريع التسليم للمشاريع العاجلة؟

ج: نعم. يتم شحن الألواح القياسية خلال ٣-٥ أيام، وتتوفر خدمة الإنتاج السريع والخدمات اللوجستية.

Office address: 26 Floor, Shibo Financial Center, Fenjiang South Road No.38, Chancheng, Foshan, GuangDong, China

Office address: 26 Floor, Shibo Financial Center, Fenjiang South Road No.38, Chancheng, Foshan, GuangDong, China  Phone

: +86 -18024913898

Phone

: +86 -18024913898 البريد الإلكتروني

: [email protected]

البريد الإلكتروني

: [email protected] IPv6 دعم الشبكة

IPv6 دعم الشبكة

اترك رسالة

اترك رسالة