تستمر تقنيات تشطيب أسطح الفولاذ المقاوم للصدأ في التطور مع سعي المصممين والمهندسين المعماريين والمصنعين إلى تحقيق استقرار أعلى، وتناسق أفضل للألوان، ومتانة معززة. ومن بين العديد من تقنيات التشطيب، طلاء مائي و الترسيب الفيزيائي للبخار (PVD) هما العمليتان الأكثر استخدامًا لـ صفائح زخرفية من الفولاذ المقاوم للصدأ.

على الرغم من أن كليهما يُضفي لونًا على الفولاذ المقاوم للصدأ، إلا أن تقنياتهما وأداءهما ونطاقات الألوان المناسبة لهما تختلف اختلافًا كبيرًا. تشرح هذه المقالة الاختلافات الرئيسية وتساعدك على اختيار التشطيب المناسب بناءً على متطلبات مشروعك.

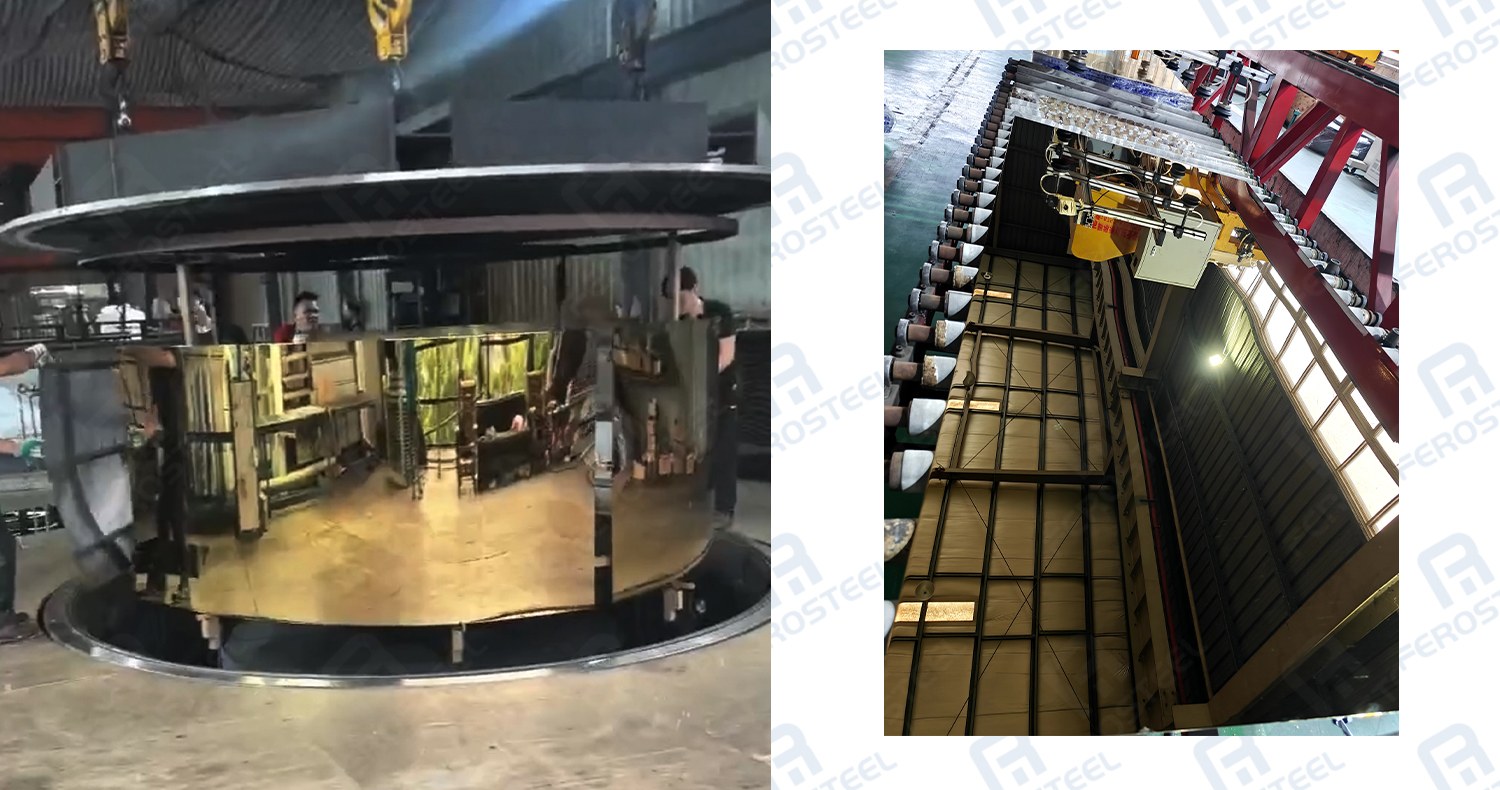

الطلاء المائي هو عملية طلاء كيميائي رطب يتم فيها ترسيب أيونات المعادن على سطح الفولاذ المقاوم للصدأ من خلال محلول إلكتروليتي. ويُستخدم عادةً للحصول على تأثيرات معدنية زخرفية بتكلفة أقل.

تتميز عملية الطلاء بالماء بخيارات ألوان محدودة للغاية بسبب الاستقرار الكيميائي للعملية.

في شركة فيروستيل، الطلاء المائي مناسب فقط للونين:

لهذه الأسباب، تقوم شركة فيروستيل لا يُنصح به طلاء مائي لأي لون آخر غير نحاس و التيتانيوم الأسودهذان اللونان هما الوحيدان اللذان يتمتعان بالتصاق ومتانة مقبولين في ظل هذه العملية.

تُعدّ تقنية الترسيب الفيزيائي للبخار (PVD) عملية طلاء أيوني فراغي تُنتج طبقة كثيفة ومتينة ومتجانسة اللون على الفولاذ المقاوم للصدأ. وتُستخدم على نطاق واسع في الديكورات المعمارية الراقية، والمصاعد، والجدران، والأسقف، والأثاث.

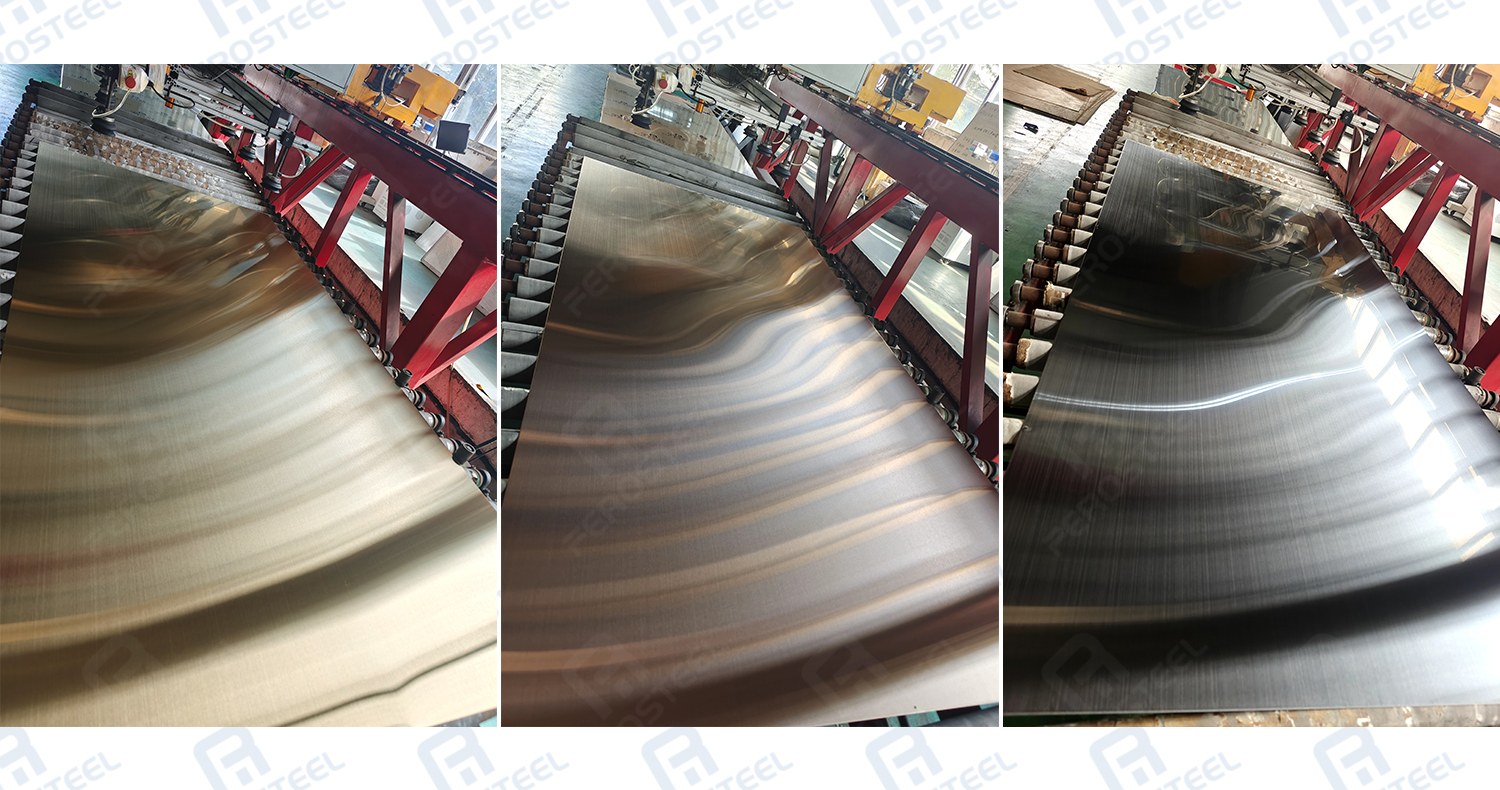

تدعم تقنية الترسيب الفيزيائي للبخار (PVD) مجموعة كاملة من الألوان الثابتة والمتينة، بما في ذلك:

ألوان PVD ثابتة ومقاومة للخدش ومناسبة للاستخدامات الداخلية والخارجية على حد سواء.

نطاق الألوان

الطلاء المائي: النحاس والتيتانيوم الأسود فقط

طلاء PVD: خيارات ألوان واسعة مع ثبات عالٍ

متانة

الطلاء المائي: منخفض، قد يبهت اللون

طلاء PVD: مقاومة عالية للخدش والبهتان

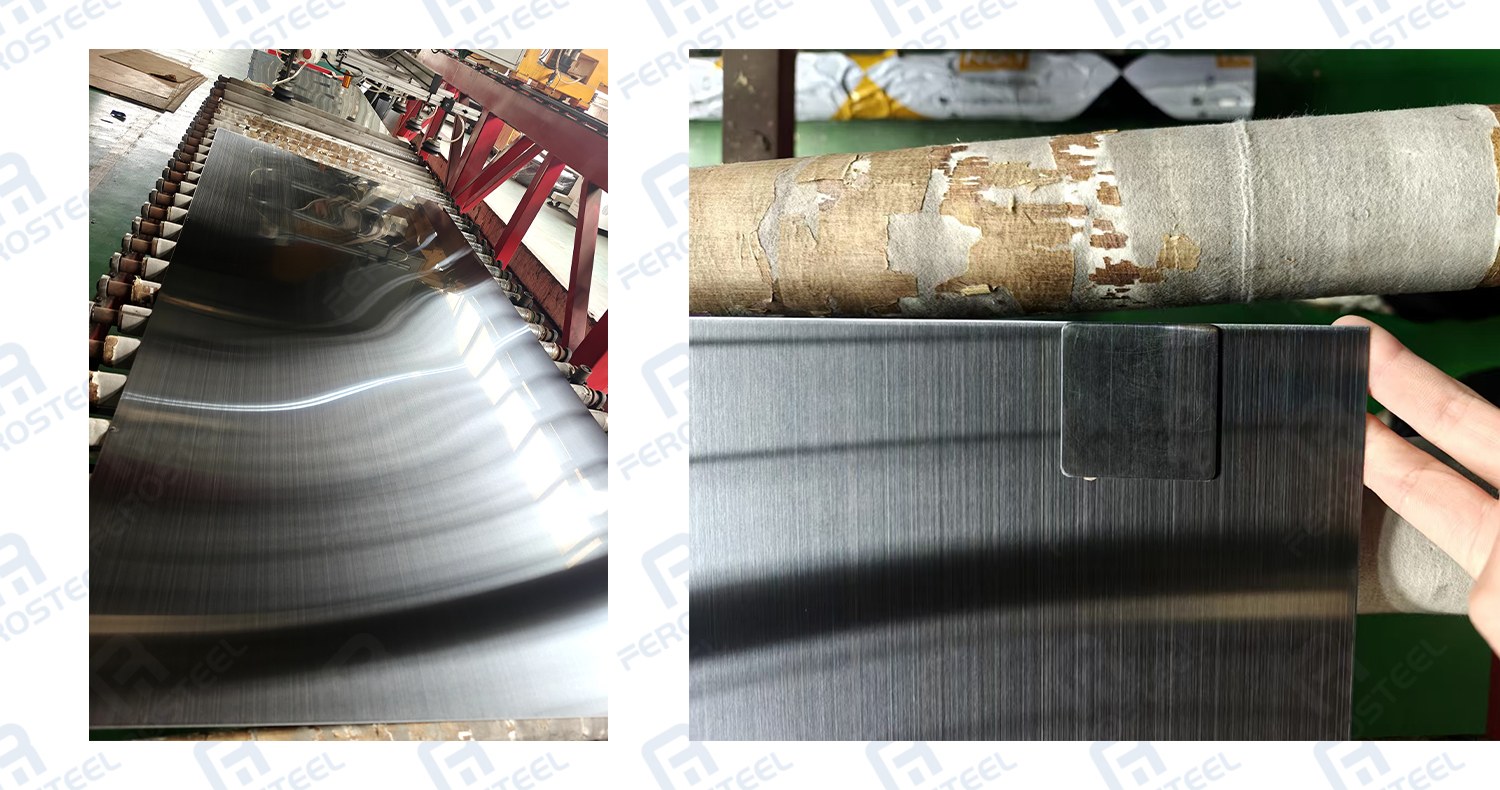

جودة السطح

الطلاء المائي: يصعب تحقيق تجانس اللون

طلاء PVD: ممتاز ومتسق

الأداء الخارجي

الطلاء بالماء: غير مستحسن

طلاء الترسيب الفيزيائي للبخار: ممتاز

يختار طلاء مائي فقط عندما تحتاج تحديدًا نحاس أو التيتانيوم الأسودوالتكلفة عامل رئيسي يجب مراعاته.

يختار طلاء الترسيب الفيزيائي للبخار لجميع الألوان الأخرى أو عندما يتطلب المشروع جودة فائقة، ومتانة طويلة الأمد، وتوحيد اللون.

بالنسبة للتصميمات الداخلية المعمارية، والأسقف، وألواح الجدران، ومشاريع الديكور الفاخرة، توصي شركة فيروستيل بشدة باستخدام صفائح من الفولاذ المقاوم للصدأ مطلية بتقنية الترسيب الفيزيائي للبخار (PVD)إن استقرار وتجانس ومتانة تقنية الترسيب الفيزيائي للبخار (PVD) تتجاوز بكثير تقنية الطلاء بالماء، مما يضمن نتائج ممتازة للتطبيقات التجارية والراقية.

1. لماذا لا يمكن للطلاء المائي أن ينتج الذهب أو الذهب الوردي؟

لأن العملية الكيميائية لا تستطيع الحفاظ على ترسب أيوني مستقر لهذه الدرجات اللونية؛ يتلاشى السطح بسرعة ويصبح غير متساوٍ.

2. هل تقنية الترسيب الفيزيائي للبخار (PVD) مناسبة للمشاريع الخارجية؟

نعم. يوفر الترسيب الفيزيائي للبخار مقاومة ممتازة للأشعة فوق البنفسجية والتآكل والظروف الجوية.

3. لماذا يفضل معظم المصممين تقنية الترسيب الفيزيائي للبخار (PVD) على تقنية الطلاء بالماء؟

لأن تقنية الترسيب الفيزيائي للبخار (PVD) توفر مقاومة أفضل للخدش، وتناسقًا أفضل للألوان، ومتانة أفضل بكثير على المدى الطويل.

4. هل يمكن لشركة فيروستيل تخصيص ألوان PVD؟

نعم. بإمكان شركة فيروستيل تعديل ألوان الترسيب الفيزيائي للبخار (PVD) بناءً على العينات أو متطلبات التصميم المحددة.

Office address: 26 Floor, Shibo Financial Center, Fenjiang South Road No.38, Chancheng, Foshan, GuangDong, China

Office address: 26 Floor, Shibo Financial Center, Fenjiang South Road No.38, Chancheng, Foshan, GuangDong, China  Phone

: +86 -18024913898

Phone

: +86 -18024913898 البريد الإلكتروني

: [email protected]

البريد الإلكتروني

: [email protected] IPv6 دعم الشبكة

IPv6 دعم الشبكة

اترك رسالة

اترك رسالة