عند اختيار مادة الفولاذ المقاوم للصدأ المناسبة للمشاريع الزخرفية أو الهيكلية، فإن فهم الاختلافات بين الفولاذ المقاوم للصدأ 201 و304 و430 و316L ضروري. كل درجة لها تركيبات كيميائية وخصائص ميكانيكية فريدة تجعلها مناسبة لتطبيقات محددة.

201 الفولاذ المقاوم للصدأ مادة اقتصادية تُستخدم غالبًا في الديكورات الداخلية وألواح المطابخ والأدوات المنزلية. تحتوي على نسبة أقل من النيكل (1-2%) ونسبة أعلى من المنجنيز، مما يجعلها أقل مقاومة للتآكل من 304، ولكن بسعر أقل.

يتميز بسهولة تشكيله، ويمكن استخدامه في الألواح الزخرفية والعناصر المعمارية غير المكشوفة. مع ذلك، فهو ليس مثاليًا للاستخدام في الأماكن الخارجية أو الرطبة.

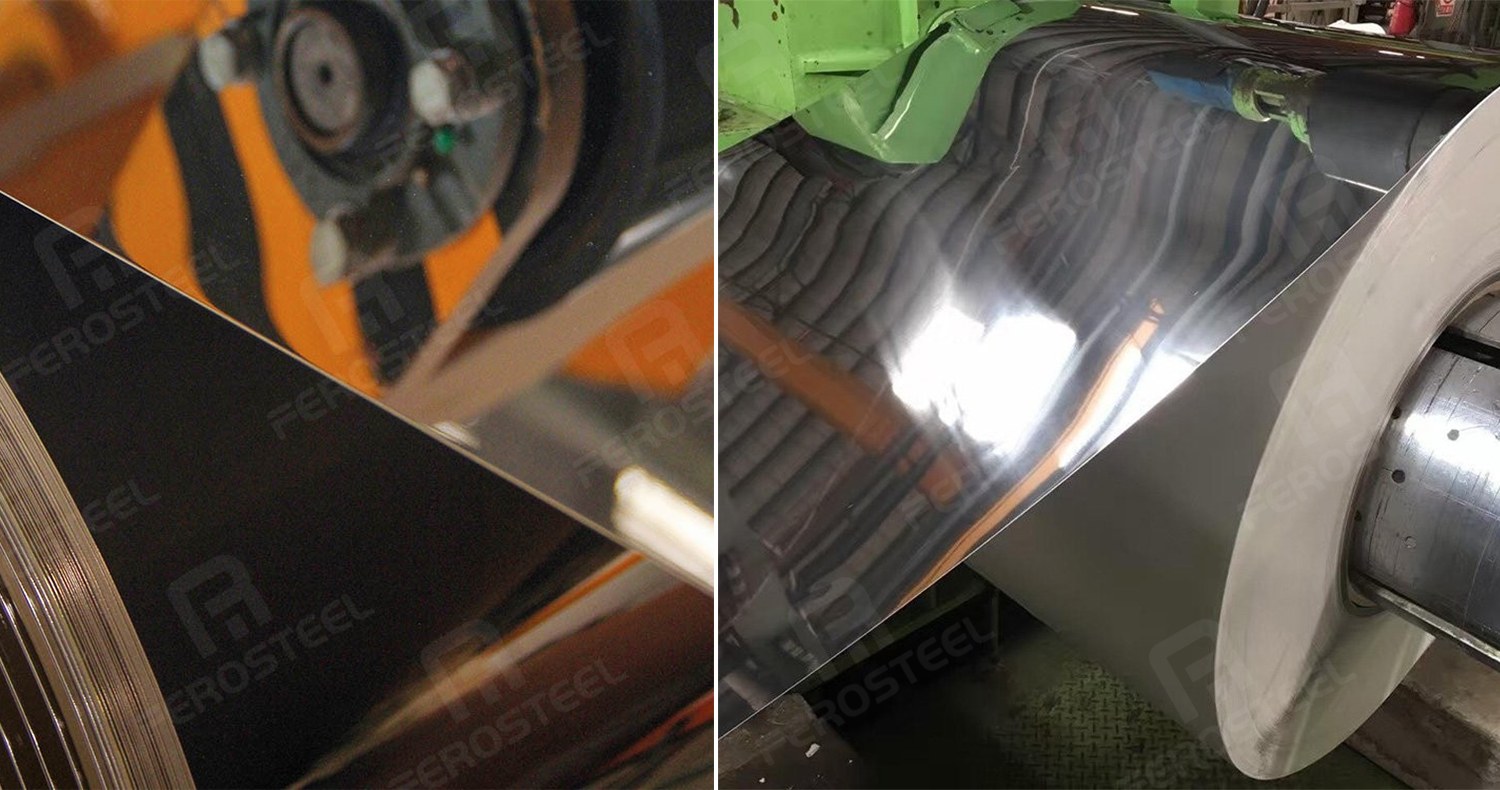

👉 يتعلم أكثر: لفائف الفولاذ المقاوم للصدأ 2B/BA للاستخدام الزخرفي

الفولاذ المقاوم للصدأ 304 هو النوع الأكثر استخدامًا في التطبيقات المعمارية والصناعية. يحتوي على نسبة تتراوح بين 8% و10% من النيكل و18% و20% من الكروم، مما يوفر مقاومة ممتازة للتآكل، ومرونةً عالية، وسطحًا أملسًا.

هذه المادة مثالية لـ أبواب المصاعد، وألواح الجدران، ومعدات المطبخ، وديكورات الأثاثإن خصائصها غير المغناطيسية ومتانتها تجعلها خيارًا شائعًا للمشاريع الحديثة.

👉 يمكنك استكشاف ملفات الفولاذ المقاوم للصدأ 304 مع تشطيبات 2B أو BA في Ferosteel:

https://www.ferosteel.com/2bba-stainless-steel-coil

430 الفولاذ المقاوم للصدأ ينتمي إلى المجموعة الفريتية، ويحتوي على ١٦-١٨٪ كروم، ولا يحتوي على النيكل. يتميز بمغناطيسيته ومقاومته المتوسطة للتآكل. هذا يجعله مناسبًا لـ كسوة الجدران الداخلية وألواح أبواب المصاعد والزخارف.

على الرغم من أنها ليست مقاومة للتآكل مثل 304 أو 316L، فإن التكلفة المعقولة لـ 430 وقابليتها الجيدة للتلميع تجعلها مثالية لـ مشاريع تصميمية مراعية للميزانية و المنشآت غير الساحلية.

الفولاذ المقاوم للصدأ 316L نسخة مُحسّنة من 304، تحتوي على 2-3% من الموليبدينوم ومحتوى كربون أقل. تتميز بمقاومة فائقة للتآكل والتآكل النقطي، خاصةً في البيئات البحرية والكيميائية والخارجية.

إنه الخيار الأفضل لـ الألواح الزخرفية الراقية والواجهات الخارجية والتطبيقات المعمارية في المناطق الرطبةيشير الحرف "L" في 316L إلى "منخفض الكربون"، مما يساعد على منع ترسب الكربيد أثناء اللحام.

| درجة | النيكل (Ni) | الكروم (Cr) | مغناطيسي | مقاومة التآكل | يكلف |

|---|---|---|---|---|---|

| 201 | 1-2% | 16-18% | بعد العمل البارد بقليل | ★★★☆☆ | قليل |

| 304 | 8-10% | 18-20% | No | ★★★★☆ | واسطة |

| 430 | 0% | 16-18% | نعم | ★★☆☆☆ | قليل |

| 316 لتر | 10-14% | 16-18% | No | ★★★★★ | عالي |

توفر شركة فيروستيل مواد الفولاذ المقاوم للصدأ المستخدمة على نطاق واسع في:

أبواب المصاعد وألواح جدران الكابينة

تصميمات السقف مع تشطيبات مطلية بتقنية PVD

الأثاث المزخرف والأسطح الداخلية

كسوات الجدران واللافتات التجارية

إذا كنت تبحث عن مصادر عالية الجودة ملفات الفولاذ المقاوم للصدأ 2B/BAتضمن مجموعة المواد الزخرفية من شركة فيروستيل المتانة والدقة واللمسات النهائية الأنيقة للسطح.

👉 قم بزيارة: https://www.ferosteel.com/2bba-stainless-steel-coil

كل درجة من الفولاذ المقاوم للصدأ لها نقاط قوتها -201 من أجل الاقتصاد، 304 لتحقيق التوازن، 430 من أجل المغناطيسية والقدرة على تحمل التكاليف، و 316 لتر لمقاومة التآكل الفائقة.

من خلال فهم هذه الاختلافات، يمكنك اختيار المادة الأكثر ملاءمة لك مشروع معماري أو زخرفي أو صناعي.

تستمر شركة فيروستيل في تقديم منتجات متميزة صفائح وملفات من الفولاذ المقاوم للصدأ المزخرفة لتلبية معايير المشروع العالمية.

Office address: 26 Floor, Shibo Financial Center, Fenjiang South Road No.38, Chancheng, Foshan, GuangDong, China

Office address: 26 Floor, Shibo Financial Center, Fenjiang South Road No.38, Chancheng, Foshan, GuangDong, China  Phone

: +86 -18024913898

Phone

: +86 -18024913898 البريد الإلكتروني

: [email protected]

البريد الإلكتروني

: [email protected] IPv6 دعم الشبكة

IPv6 دعم الشبكة

اترك رسالة

اترك رسالة