مع تزايد تركيز العمارة والتصميم الداخلي الحديث على التفاصيل، أصبحت أسقف الفولاذ المقاوم للصدأ ذات التموجات المائية الخيار الأمثل للعديد من المصممين وأصحاب المنازل. لا تقتصر هذه المادة على مظهرها الخارجي الفريد فحسب، بل تتميز أيضًا بالقوة والمتانة وسهولة الصيانة، مما يجعلها مثالية لمختلف المساحات التجارية والسكنية. ستقدم هذه المقالة شرحًا لعملية تصنيع أسقف الفولاذ المقاوم للصدأ ذات التموجات المائية، ومزاياها، وكيفية اختيار المادة المناسبة لمشروعك.

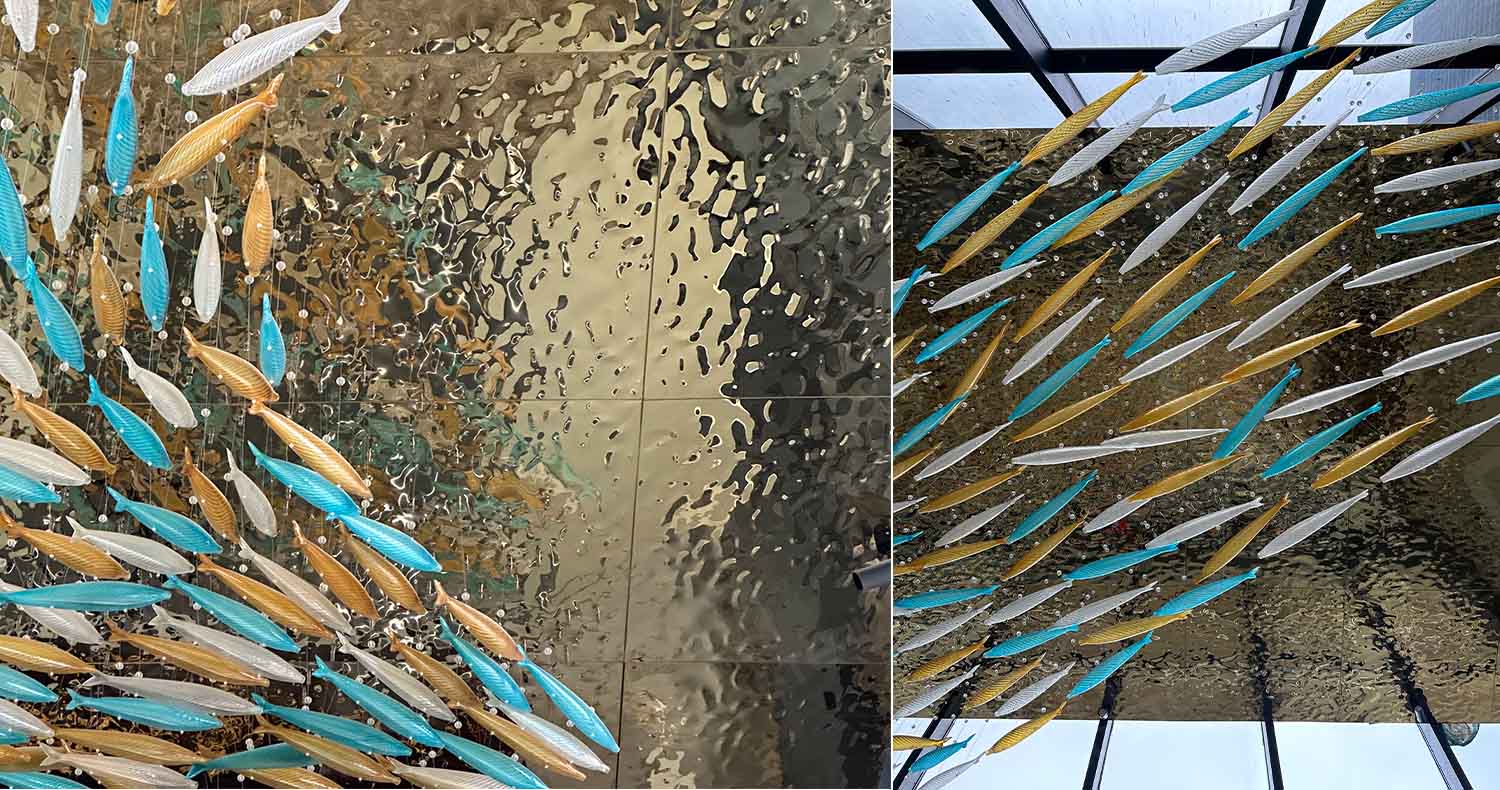

سقف الفولاذ المقاوم للصدأ ذو التموجات المائية هو مادة زخرفية مصنوعة من ألواح فولاذ مقاوم للصدأ عالي الجودة تخضع لعمليات خاصة لتشكيل نمط متموج على السطح. يسمح تأثير التموج الفريد للضوء بالانكسار على السقف، مما يخلق تجربة بصرية ديناميكية. في التصميم الداخلي، لا يعزز الفولاذ المقاوم للصدأ ذو التموجات المائية الجاذبية الجمالية للمساحة فحسب، بل يضيف أيضًا عمقًا ويوفر تجربة بصرية استثنائية.

يتضمن إنتاج صفائح الفولاذ المقاوم للصدأ ذات التموجات المائية عدة خطوات دقيقة لضمان الحصول على نتيجة مثالية لكل صفائح. أولاً، يختار المصنعون مواد الفولاذ المقاوم للصدأ المناسبة، وعادةً ما يكون الفولاذ المقاوم للصدأ 304 و316 خيارين ممتازين لمقاومتهما الممتازة للتآكل ومتانتهما العالية، مما يجعلهما مثاليين للأغراض الزخرفية. بعد ذلك، يُستخدم برنامج التصميم بمساعدة الحاسوب (CAD) لتصميم نمط التموج، والذي يُحفر بعد ذلك على سطح المعدن باستخدام تقنيات ضغط عالية الدقة.

بمجرد ضغط تأثير التموج على السطح، تخضع الألواح للتلميع أو الطلاء أو الطلاء الكهربائي لضمان لمعانها ومتانتها الكافية. يمنح التلميع الألواح مظهرًا كالمرآة، مما يعزز قدرتها على انعكاس الضوء، بينما يوفر الطلاء الكهربائي والطلاء خيارات ألوان أكثر ويوفران حماية إضافية لمقاومة الأكسدة.

الجاذبية الجمالية

تُضفي أسقف الفولاذ المقاوم للصدأ ذات التموجات المائية لمسة فنية فريدة تُضفي جمالاً فريداً على المكان. تُكسر أنماط التموج رتابة الأسقف المسطحة التقليدية، وتعكس الضوء بطرق مُتنوعة، مُعززةً التأثير البصري للغرفة بأكملها.

متانة عالية

من أهم مميزات الفولاذ المقاوم للصدأ مقاومته الممتازة للتآكل. حتى في البيئات الرطبة أو ذات درجات الحرارة العالية، تحافظ أسقف الفولاذ المقاوم للصدأ المقاومة للماء على ثباتها. هذا يجعلها مثالية للاستخدام في المساحات التجارية والفنادق والمستشفيات وغيرها من الأماكن التي تتطلب مواد عالية الأداء.

سهلة التنظيف والصيانة

السطح الأملس لأسقف الفولاذ المقاوم للصدأ المقاومة للماء يجعلها سهلة التنظيف، حيث يصعب على الغبار والبقع الالتصاق بها. التنظيف المنتظم لا يتطلب سوى المسح بقطعة قماش مبللة، ويُنصح بتجنب المواد الكيميائية القاسية أو الأدوات الكاشطة لمنع خدوش السطح. هذا يجعلها مناسبة بشكل خاص للبيئات التي تتطلب معايير نظافة عالية، مثل المطاعم والمستشفيات والأماكن العامة.

تطبيق متعدد الاستخدامات

يُستخدم الفولاذ المقاوم للصدأ ذو التموجات المائية ليس فقط في الأسقف، بل أيضًا في تكسية الجدران والجدران، وحتى في أسطح الأثاث. بفضل تصاميمه وألوانه المتنوعة، يُلبي احتياجات مختلف أنماط المساحات، من التصاميم الحديثة والبسيطة إلى التصاميم الفاخرة.

عند اختيار سقف من الفولاذ المقاوم للصدأ ذي تموجات مائية، من الضروري مراعاة نمط المساحة والغرض منها. بالنسبة للمساحات التجارية، يُنصح باختيار مواد ذات انعكاس ضوء أقوى وأنماط تموج متجانسة لإضافة عمق وإشراق. أما بالنسبة للتصاميم السكنية، فيمكن اختيار تأثيرات تموجات أكثر نعومة لخلق جو دافئ ومريح.

بالإضافة إلى ذلك، تُعدّ معالجة السطح عاملاً مهماً في اختيار المواد. إذا كنتَ بحاجة إلى أسقف أكثر متانة، فاختر صفائح الفولاذ المقاوم للصدأ المقاومة للماء والمُعالجة بالكهرباء أو الطلاء، لأنها تُحسّن مقاومة الأكسدة، مما يجعلها أكثر ملاءمة للاستخدام طويل الأمد.

يتطلب تركيب أسقف الفولاذ المقاوم للصدأ ذات التموجات المائية فنيين متخصصين. عادةً ما يتم تركيب السقف باستخدام نظام السقف المعلق، حيث تُعلق أو تُثبت صفائح الفولاذ المقاوم للصدأ على هيكل السقف الحالي. لضمان ثبات السقف وجماله، من المهم محاذاة الصفائح بدقة أثناء التركيب. عند الحاجة، يُمكن لفريقنا تقديم خدمات تركيب احترافية ودعم فني لضمان سير العملية بسلاسة.

أسقف الفولاذ المقاوم للصدأ ذات التموجات المائية ليست مجرد مواد ديكورية جميلة فحسب، بل تتميز أيضًا بمتانة استثنائية وسهولة في الصيانة. وهي مثالية للاستخدام في مختلف المساحات التجارية والسكنية. بفضل عمليات التصنيع الدقيقة، تضفي أسقف الفولاذ المقاوم للصدأ ذات التموجات المائية لمسة فنية فريدة على مساحتك وتُحسّن التصميم العام. إذا كنت تبحث عن مواد أسقف عالية الجودة من الفولاذ المقاوم للصدأ، فيروستيل هو شريكك المثالي.

1. كم تكلفة سقف تموج الماء المصنوع من الفولاذ المقاوم للصدأ؟

يختلف سعر سقف الفولاذ المقاوم للصدأ المُتموج باختلاف المادة والحجم والتصميم ومعالجة السطح. تواصل معنا للحصول على عروض أسعار مُخصصة تُناسب احتياجاتك.

2. هل يمكن استخدام أسقف الفولاذ المقاوم للصدأ المتموجة بالماء في الهواء الطلق؟

نعم، يتم معالجة أسقفنا المصنوعة من الفولاذ المقاوم للصدأ ذات التموجات المائية بمعالجات سطحية متخصصة، مما يجعلها مقاومة للغاية للتآكل ومناسبة للبيئات الخارجية أو الرطبة.

3. كيف أقوم بتنظيف سقف الفولاذ المقاوم للصدأ المموج بالماء؟

التنظيف بسيط، ما عليك سوى مسح السطح بقطعة قماش مبللة. يُنصح بتجنب استخدام المنظفات الكيميائية القاسية أو الأدوات الكاشطة لتجنب الخدوش.

4. هل تركيب أسقف الفولاذ المقاوم للصدأ المتموجة بالماء أمر معقد؟

يتطلب التركيب مساعدةً احترافيةً لضمان دقة وثبات وضع ألواح السقف. نقدم دعمًا كاملًا لضمان سلاسة عملية التركيب.

Office address: 26 Floor, Shibo Financial Center, Fenjiang South Road No.38, Chancheng, Foshan, GuangDong, China

Office address: 26 Floor, Shibo Financial Center, Fenjiang South Road No.38, Chancheng, Foshan, GuangDong, China  Phone

: +86 -18024913898

Phone

: +86 -18024913898 البريد الإلكتروني

: [email protected]

البريد الإلكتروني

: [email protected] IPv6 دعم الشبكة

IPv6 دعم الشبكة

اترك رسالة

اترك رسالة